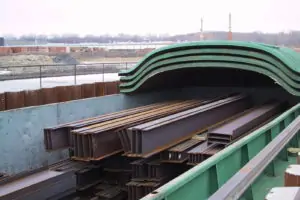

I-beams, also known as H-beams, are essential structural components commonly used in construction as both beams and columns. Their name comes from their distinctive cross-sectional shape, which resembles the letter “I” or “H.” Each beam features horizontal elements called flanges and a vertical element known as a web, enabling the I-beam to handle various types of loads effectively.

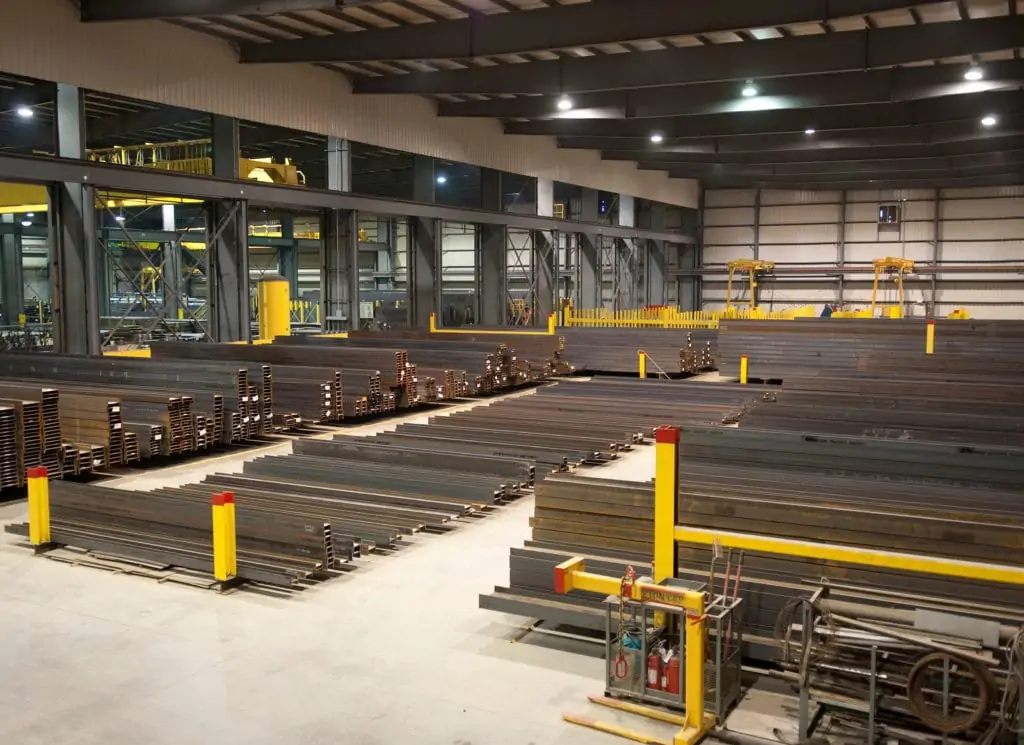

At Delta Steel, we supply high-quality structural steel I-beams in a broad range of sizes, lengths, and specifications to suit the demands of your project.

Benefits of I-Beams

I-beams are a popular choice for commercial structures thanks to their strength, efficiency, and cost-effectiveness. From framing to critical supports, they are durable solutions for a wide range of construction and engineering applications. Their relatively lightweight design and compact footprint make them easy to handle and install, often reducing the need for bulky support walls or columns.

In addition to being easy to work with, steel I-beams offer impressive load-bearing capacity. They efficiently distribute weight from top to bottom, maintaining structural integrity with fewer beams. I-beams are typically available in lengths up to 60 feet and are commonly used to support spans ranging from 30 to 100 feet.

Applications

Steel I-beams are valued in construction and engineering for their strength, stability, versatility, and cost-effectiveness. Their design allows them to withstand a range of stresses: the web resists shear forces, while the flanges offer good unidirectional bending properties. These characteristics make steel I-beams ideal for load-bearing applications such as:

- Commercial construction: Framing buildings like hospitals, parking garages, and skyscrapers in both horizontal and vertical directions

- Residential projects: Providing structural support for floor joists and lintels

- Bridge construction: Offering critical load-bearing strength in bridges and other infrastructure projects

Specifications

An I-beam generally has tapered flanges and a web that is wider than each flange. The following I-beam dimensions determine the component’s load-bearing capacity, weight, and fit for a given application:

- Depth (D): The I-beam’s total height

- Flange width (W): The horizontal width of the bottom and top flanges

- Flange thickness (T): The flanges’ thickness

- Web thickness (t): The vertical web section’s thickness

- Weight per unit length: Often measured in pounds per foot or kilograms per meter

At Delta Steel, we offer these structural steel grades for I-beam products:

- ASTM A36: This specification applies to carbon structural steel products used in bolting, riveting, or welding applications for buildings, bridges, and general structural use.

- ASTM A709: Used for carbon and high-strength, low-alloy materials, this specification applies to I-beams, bars, and other shapes used in bridges.

- ASTM A992: This specification covers rolled structural steel products used in bridges, building framing, and other structural applications.

- ASTM A588: This is the standard for high-strength, low-alloy structural steel intended for use in welded buildings and bridges where enhanced durability and lighter weight are priorities.

- ASTM A572: This specification covers the five grades of high-strength, low-alloy steel used in welded, bolted, or riveted bridge construction.

I-Beams at Delta Steel

I-beams are an essential element in buildings, bridges, parking garages, and other construction applications. As a leader in the structural steel market, Delta Steel provides steel I-beams and other products to industries such as construction, infrastructure, power and communications, renewable energy, and marine. We offer an extensive inventory to meet our customers’ exact specifications and requirements. With our state-of-the-art processing equipment, just-in-time delivery, and commitment to customer satisfaction, you can count on Delta Steel for quality structural steel I-beams.

Request a quote today for your next project.